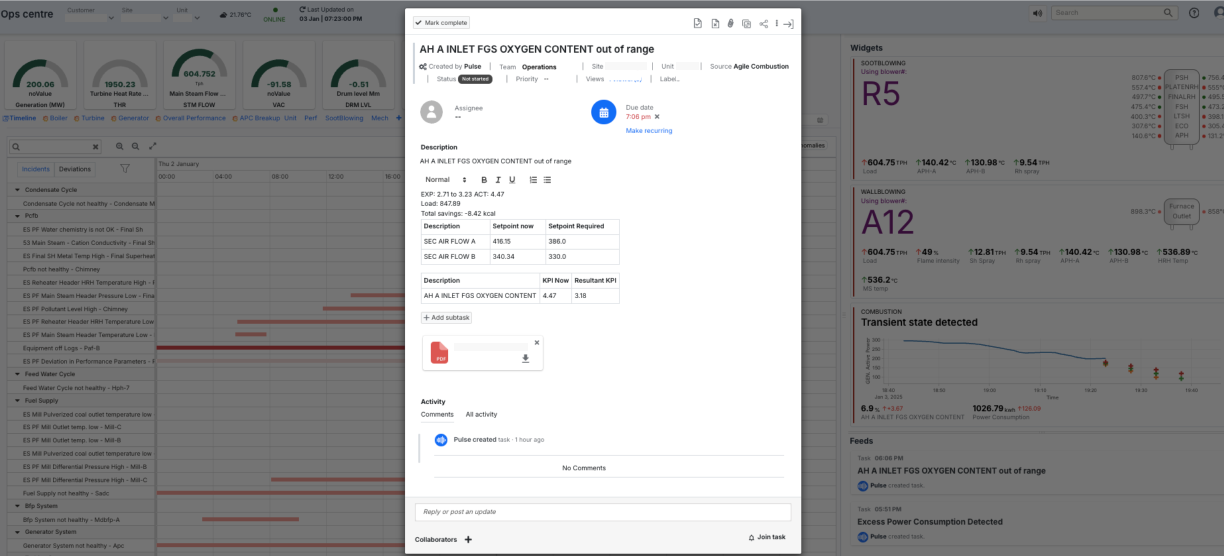

Pulse from ExactSpace is a revolutionary AI-powered digital twin technology that transforms industrial operations. Predict equipment failures, optimize processes, and unlock unprecedented operational intelligence that goes beyond traditional analytics.

Revolutionize your operations with our advanced AI-powered digital twin solutions

Integrating our Digital Twins with your assets is like having an expert caring for each of your assets, listening intently to all subtle signals and ensuring it gets your attention just when needed. Our AI continuously monitors equipment health, predicts maintenance needs, and prevents costly downtime.

Predictive models pick up early signals of asset deterioration

Diagnostic models provide expert-like root cause analysis

Collaboration framework that drives timely actions to avoid failures

Process Twins are your plant's supercharged AI assistants helping you make the most accurate operational decisions every single time. Optimize your process to meet plant objectives like reduce energy consumption, improve product quality and cut down waste.

Create process linkage models to establish connections between various sections of your plant.

Let the twin know what your process objectives are and the boundaries in which it must operate

Allow an ensemble of neural network transformer models to learn from your data and recommend precise operating setpoints to achieve your goals

Enterprise-grade capabilities engineered for industrial transformation and operational excellence

Deploy Pulse® seamlessly across any infrastructure - public cloud, private cloud, or on-premise environments with complete flexibility and control.

Pulse Edge enables instant connectivity with comprehensive industrial protocols and data sources for seamless integration.

Transform raw sensor data into actionable insights without writing a single line of code through intuitive drag-and-drop interfaces.

Comprehensive security framework with end-to-end encryption and advanced threat protection for mission-critical operations.

Intelligent auto-scaling architecture that adapts to your data volume and processing needs automatically for optimal performance.

Create sophisticated dashboards and real-time visualizations in under 10 minutes with our intuitive design interface.

Pulse has already been deployed for over 50 Asset Classes. Your plant can benefit from these plug-and-play models to speed up time-to-value from predictive analytics.

Discover how Pulse® Digital Twin technology is transforming industrial operations across different sectors with proven results and measurable impact.

Transform your power plant efficiency with AI-powered boiler optimization. Our Digital Twin technology continuously monitors combustion parameters, predicts equipment failures, and optimizes fuel consumption to deliver significant cost savings and enhanced reliability.

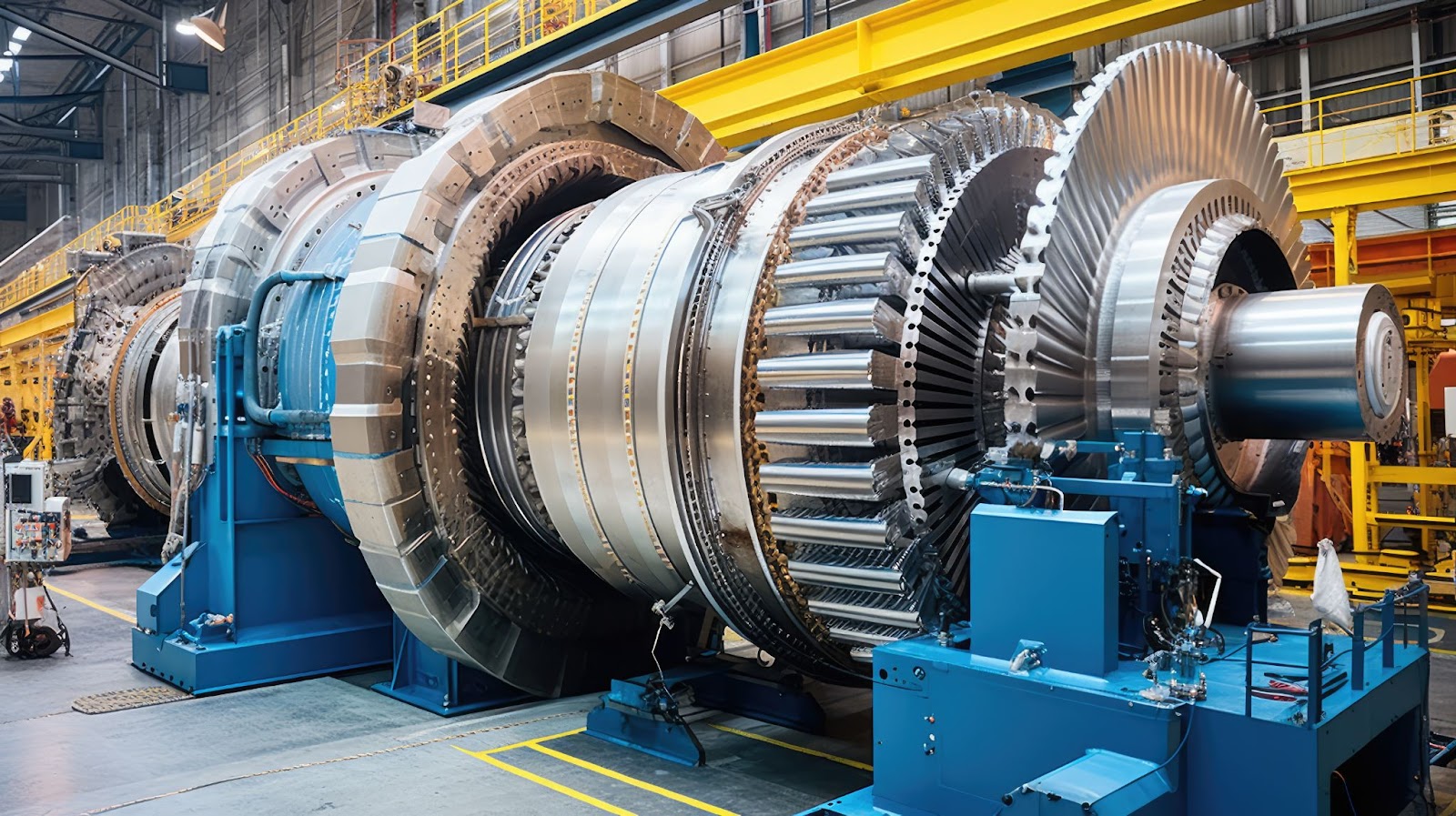

Enhance steam turbine performance and reliability with AI-powered predictive analytics. Our Process Twin technology continuously monitors turbine health, predicts component failures, and optimizes operational parameters to maximize efficiency and extend equipment lifespan. This comprehensive approach delivers substantial operational savings and improved asset performance.

Optimize condenser performance with AI-powered monitoring and predictive analytics. Our Process Twin technology prevents fouling, optimizes cooling systems, and ensures peak thermal efficiency while reducing energy waste and operational costs.

Optimize clinker cooler performance with Pulse's Intelligent Digital Twin technology. Our solution provides data-driven approaches to improve cooler efficiency, enable precise heat recovery, reduce energy consumption, and enhance process stability while boosting power generation from Waste Heat Recovery Systems.

Revolutionize steel production with AI-powered cobble prediction. Pulse monitors mill temperature, tension, and rolling speed in real-time to prevent dangerous cobble incidents, ensuring safer operations and continuous productivity.

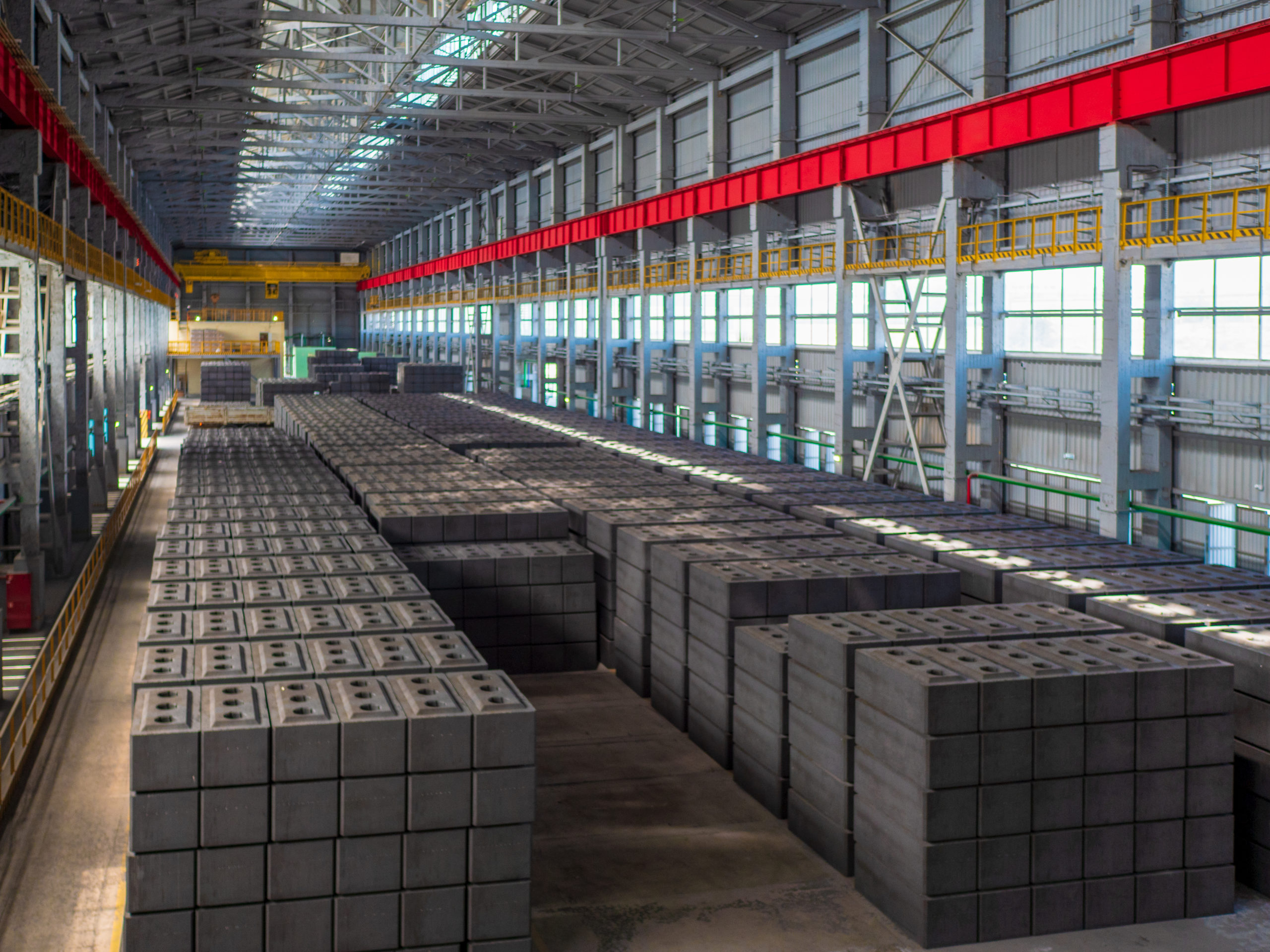

Optimize aluminum anode production with intelligent process control. Our Process Twin technology monitors raw material quality, optimizes compaction settings, and ensures consistent anode density while reducing rejection rates and production costs.

Transform your power plant efficiency with AI-powered boiler optimization. Our Digital Twin technology continuously monitors combustion parameters, predicts equipment failures, and optimizes fuel consumption to deliver significant cost savings and enhanced reliability.