The efficient operation of clinker coolers plays a crucial role in optimizing energy use in cement production. Pulse's Intelligent Digital Twin provides a data-driven approach to improving cooler performance, addressing inefficiencies, and maximizing outcomes. It enables precise heat recovery, lowers specific energy consumption, enhances process stability, and boosts power generation from Waste Heat Recovery Systems. This innovative solution supports cement plants in achieving higher efficiency, sustainability, and profitability.

High variability in air temperatures, WHRS power generation, cooler-specific air, compartment pressures, and cooler stroke indicates that cooler bed thickness is not maintained correctly. This leads to inefficient cooler operation, preventing consistent and maximum heat recovery for both power generation and recirculation to the kiln.

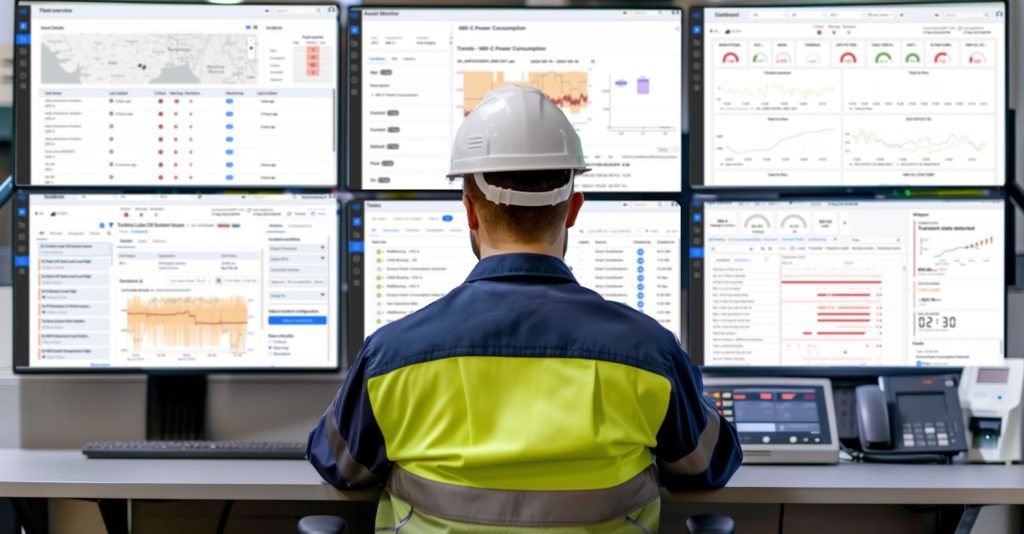

Automating real-time monitoring of cooler operations is essential to address these inefficiencies. With Pulse, cement manufacturers can enhance cooler performance, maximize energy recovery, and achieve greater operational efficiency, driving cost savings, stable operations, and improved sustainability.

The cement industry operates in a complex environment where maintaining precision and consistency is critical for product quality. However, traditional systems often fall short in managing operational variability, particularly in cooler operations. Key challenges include:

To address these challenges and optimize cooler operations Pulse integrates seamlessly with existing control systems and provides a suite of advanced solutions. These solutions are designed to enhance performance, reduce inefficiencies, and ensure consistent, cost-effective operations.

Pulse continuously monitors critical parameters like compartment pressures, airflows, and bed height in real-time. Its self-learning algorithms dynamically adjust cooler operations to ensure optimal heat recovery and process stability under changing conditions, eliminating inefficiencies caused by static control systems.

By utilizing advanced AI and machine learning, Pulse optimizes heat transfer and cooler efficiency, improving overall thermal performance and significantly reducing energy consumption and waste.

Pulse monitors the health of cooler components and provides early warnings about wear and tear. By leveraging real-time anomaly detection and root cause analysis, it ensures proactive interventions, minimizes downtimes and extends equipment lifespan while avoiding reactive, post-mortem failure analysis.

Pulse stabilizes coal usage by dynamically adjusting cooler parameters. This ensures consistent heat recovery, stabilizes kiln operations and reduces fuel costs.

Pulse seamlessly adapts to changes in clinker composition, ambient conditions, and production demands. This ensures consistent cooler performance without manual intervention, overcoming the limitations of traditional PID systems.

Pulse ensures precise recalibration of cooler stroke by analyzing airflow dynamics and compartment pressures accurately. This prevents inaccuracies in bed height management and maintains the balance between SA/TA vs. mid-air temperatures for optimal heat recovery to the kiln and WHRS.

Pulse's Intelligent Digital Twin has delivered measurable improvements in cement plant operations:

Improved waste heat recovery enhances MW generation, stabilizes kiln operations, and boosts overall plant efficiency, resulting in significant energy cost reductions.

Pulse helps lower overall coal consumption during stable kiln operation, resulting in cost savings and a reduced carbon footprint.

Continuous monitoring and optimization ensure that the cooler operates efficiently, contributing to better kiln stability and smoother plant operations. This reduces downtime and maintenance costs, further enhancing the overall performance of the cement plant.

Optimizing cooler performance directly impacts the plant's ability to recover waste heat, improving energy efficiency and reducing reliance on external energy sources.

Pulse empowers cement plants to achieve long-term operational excellence by enabling smarter, data-driven decisions. Its focus on enhancing efficiency, reducing energy waste, and ensuring consistent performance translates into measurable benefits for both sustainability and profitability.

With Pulse, cement manufacturers can confidently embrace innovation to stay competitive in an evolving industry. The solution's ability to adapt to changing conditions, optimize energy recovery, and provide predictive insights makes it an essential tool for modern cement operations.

By implementing Pulse's Intelligent Digital Twin, cement plants can achieve higher efficiency, sustainability, and profitability while maintaining the precision and consistency critical for product quality in today's competitive market.

Discover how Pulse® Digital Twin technology can optimize your cement plant processes and deliver measurable results.

Get Started Today