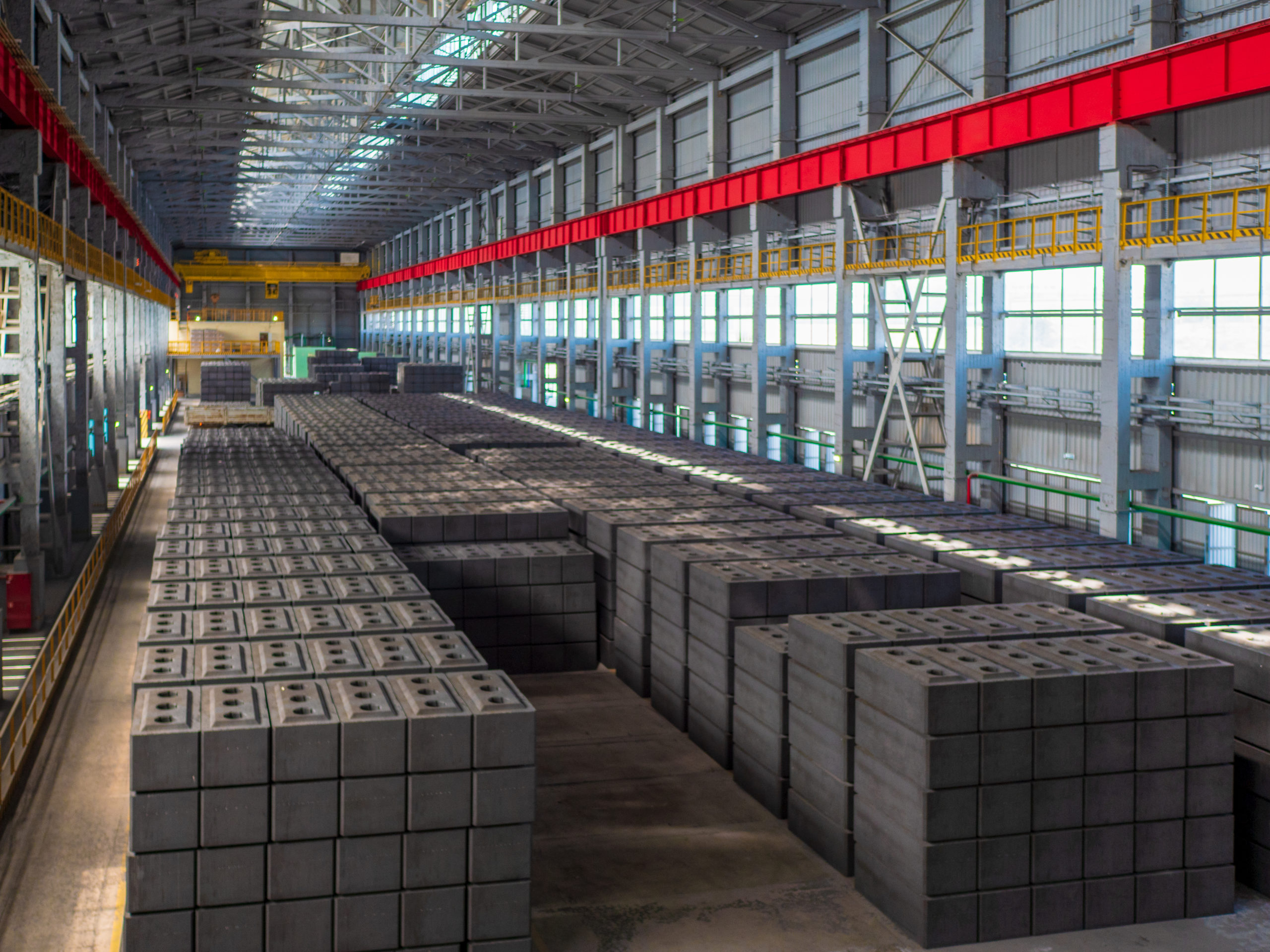

In the aluminum industry, it is important to produce high-quality green anodes to ensure better efficiency of the smelting process. Green Anode Plants (GAP) face many challenges, such as variability in raw materials, process inconsistencies, and dependency on manual operations, which lead to increased rejection rates and a drop in Anode quality. These challenges directly impact the cost of production, the amount of energy consumed, and the quality of downstream processes.

Pulse, an Intelligent Digital Twin, improves GAP operations by using real-time data, optimizing workflows, and offering helpful insights. Through predictive modeling and data-driven decision-making, Pulse solves issues to enhance the efficiency of processes and the quality of products in GAP.

In traditional GAP operations, variations in raw material quality, like petroleum coke and pitch, cause inconsistencies in anode density and resistivity. Visibility and analysis of data from different parts of the GAP process - raw material storage, grinding and crushing, paste preparation, and compaction - is a challenge given the extremely dynamic operations. This leads to inaccurate decisions in real time and eventually affects the final product quality.

There was a need for a system that could resolve all these issues and make the GAP process more efficient and predictable.

The major challenges in GAP operations include:

These challenges highlighted the need for a solution that could deliver real-time adaptability, consistency, and efficiency in GAP operations.

Pulse addresses these challenges with its AI-driven optimizing engine in several ways:

It collects data from sensors across all sections of the plant, from raw material silos to the anode baking furnace. This approach ensures every aspect of the process is monitored.

Pulse uses advanced AI to predict the quality of raw material and recommends changes to the recipe for anodes dynamically to ensure consistency in key properties like density and electrical resistivity.

Pulse identifies the best compaction settings and GSD to reduce cracking and rejections. It also suggests ideal operating ranges to maintain consistent KPIs. Pulse identifies the best operational ranges and provides actionable recommendations to operators for maintaining optimal GSD, compaction, and other critical settings. This reduces rejection rates and improves KPIs.

Pulse gives operators real-time suggestions to improve the decision-making and efficiency of processes, reducing the need for manual adjustments.

Pulse generates detailed reports highlighting anomalies and their root causes, enabling continuous improvement and better operational planning.

With lower rejection rates, less material is wasted, and production costs are reduced. The improved consistency in anode quality also enhances downstream processes, like smelting, saving energy and resources.

Implementing Pulse in GAP operations has resulted in measurable improvements:

Anode rejection dropped from 3.4% to 2.2%, significantly decreasing material wastage.

The standard deviation of anode density improved by 30% (from 0.01 to 0.007).

Consistent anode quality reduces energy requirements in downstream smelting processes.

Real-time insights enable better process control, minimizing manual errors and variability.

Pulse's Intelligent Digital Twin solutions transform Green Anode Plant operations by addressing issues like variability and inefficiencies. With real-time data and predictive analytics, Pulse improves anode quality, lowers rejection rates, and improves energy efficiency.

By implementing Pulse, aluminum manufacturers can achieve consistent, high-quality green anode production while reducing operational costs and environmental impact. The solution's comprehensive approach ensures sustainable improvements in both productivity and product quality, positioning companies for long-term success in the competitive aluminum industry.

Discover how Pulse® Digital Twin technology can transform your aluminum manufacturing operations and deliver exceptional quality results.

Get Started Today